The Recycling Industry Operating Standard is a management system that combines best practices in Quality, Environment, and Health and Safety. Initially released in 2006, the revised version RIOS™:2016 adapted to the needs of the recyclers and accommodated contemporary management system practices. Apart from electronic recyclers, repair facilities, and refurbishers, RIOS has been implemented by recyclers of different commodities like paper, plastic, rubber, and metals.

What is RIOS?

The RIOS serves as one integrated and streamlined management system for compliance with manufacturing-centric ISO standards (ISO 14001, ISO 9001, and ISO 45001:2018). It is a DIY system built as per the rules and requirements of the RIOS standard. This ANAB-accredited1 standard is developed by the Institute of Scrap Recycling Industries (ISRI) which rebranded itself as the Recycled Materials Association (ReMA) in April 2024. It is developed for recyclers and is based on the concepts of the Plan-Do-Check-Act model. The stated requirements in the standard are not prescriptive in nature, but are a plan of action for recyclers to evaluate, understand, and eliminate QEHS risks within the system. e-Stewards certification approves EMS of the RIOS as an alternative to the required ISO 14001.

How is RIOS Certification Significant for ITADs and Recyclers?

RIOS certification is beneficial for recyclers as well as ITADs that provide recycling as their core disposition service. This enables consistent, secure, and environmentally responsible handling of retired IT assets. RIOS not only supports compliance with regulatory requirements but also aligns with R2v3 certification, serving as an approved EHSMS under the R2 standard. For ITADs and recyclers that aim to build trust, win contracts, and operate in a sustainable manner, RIOS helps get a competitive advantage.

Some of the key aspects of the RIOS management system standard that help ITADs are:

- Quality: A certified quality management system ensures stakeholders have remarkable experiences consistently by evaluating operations, producing auditable procedures, and delivering high-quality products. Not only are the specific requirements of the customers accommodated into the system but product returns and chargebacks are also prevented. The dissemination of information which includes material inflow management, and conveying the intricacies of a recycling facility to local emergency responders, improves relationships with the stakeholders.

- Environment: With the framework created by the RIOS management system, facilities can monitor and review their impact on the environment including concerns around air, noise, water pollution, energy consumption, as well as positive impacts like production of recyclables. Such evaluation helps facilities in seeking means to reduce their carbon footprint. The framework also supports complying with applicable environmental regulations, and reducing or preventing the facility from getting fined. The RIOS certification and implementation of an environmental management system earn the facility community recognition and marketing opportunities.

- Health & Safety: The RIOS implementation guide includes tools and templates with systemic consideration of risks, proper training, and corresponding guidelines. The RIOS process enables an ITAD facility or a recycler to evaluate areas for possible safety hazards and make engineering and procedural changes to reduce the probability and impact of a safety incident. The auditable set of instructions serves as a how-to reference guide for employees, and a mechanism for management to ensure work is performed in a safe manner. To ensure employees are adequately trained to fulfill their responsibilities in a safe space, facilities will monitor their training programs. The RIOS management system empowers employees to report misses, pitch new ideas, and contribute to the development of a safe working environment. It also provides a framework to monitor ISO:45001 regulations and ensure consistent compliance.

- Compliance: RIOS promotes a culture of continuous improvement through internal audits, root cause analysis, and performance monitoring to not only ensure compliance but also enhance productivity and efficiency. The facilities certified by RIOS can use their management systems to demonstrate their compliance adherence to regulatory bodies in order to avoid full inspections.

How Can Recyclers Get RIOS Certified?

To be on the way toward RIOS certification, recyclers need to get a membership. There are two levels of memberships: Management Track Membership and Certification Track Membership. While the RIOS Implementation Guide (RIG), video-based training programs, etc., are available to both memberships, the certification track membership permits a recycler to advertise that they are RIOS-certified. With the management track membership, recyclers can implement a RIOS system without having to pass a third-party audit. There are three ANAB-accredited bodies that grant certification to applicant recycler companies.

Getting an RIOS certification is a 7-step process that involves:

- Fill out the RIOS membership application to sign up for the membership.

- Implement the RIOS management system using the RIOS Implementation Guide (RIG) and RIOS training programs.

- Select a certification body and an auditor.

- An internal audit is performed and non-conformances are eliminated.

- A stage-1 audit is conducted by a third-party to review all the documentation requirements of the facilities.

- In the stage 2 audit, the third-party auditor reviews the operations of the recycler facility that include ensuring training requirements are being met, procedures are being followed by the management and employees, and laws and regulations are being adhered to. The non-conformances detected, if any, are eliminated.

- If the RIOS certification audit is found to be successful, then the RIOS staff is notified. The certified recyclers can find their facility on the “Find a RIOS Certified Recycler Tool” page on the RIOS certification website.

Although RIOS is a DIY system, companies often take the assistance of consultants to minimize their QEH&S risks. As long as it is understood that the RIOS management system is a tool that requires consistent developments and people managing it to understand it completely.

Here is How RIOS Aligns With R2v3

The maintenance of a certified Environmental, Health, and Safety Management System (EHSMS) is a core requirement for an R2 facility as per the SERI’s R2v3 implementation guide. Provision 4 of this guide recommends that the R2 facility follows RIOS clauses to assess the consistency of the EHSMS. In other words, RIOS is an approved EHSMS under the R2v3 standard. RIOS-certified recyclers can easily fulfill the requirements of SERI’s R2v3.

R2v3, Section 1(3) EH&S Management System of Core Requirements specifies that:

- For planning and managing the EH&S aspects of an R2 facility’s operations, it should be certified to at least one of the approved EHSMS standards by an accredited certification body.

- The requirements of the R2 standard should be completely integrated into the EHSMS by the facility, including records and documents essential for proving compliance with all the requirements. The facility should also review the system at least once a year through internal audits.

- The availability and maintenance of all the records and documents essential for proving compliance with the R2v3 standard at the certified facility should be ensured by the R2 facility.

Additionally, RIOS requires ITADs and recyclers to follow a Quality Management System (QMS) as a part of an integrated approach to manage their processes efficiently especially for those handling the disposal of IT assets. Quality assurance is a key requirement for enabling device reuse as per Provision 6 of the R2v3 Implementation Guide. This QMS component is necessary for ITADs for ensuring services delivered such as data destruction, testing, repairing, or material recovery are consistent and meet customer and regulatory requirements. For ITADs following a QMS under RIOS means standardizing processes like device inflow, asset tracking, data wiping, record keeping, erasure verification, and refurbishment – at all steps, quality is to be assured.

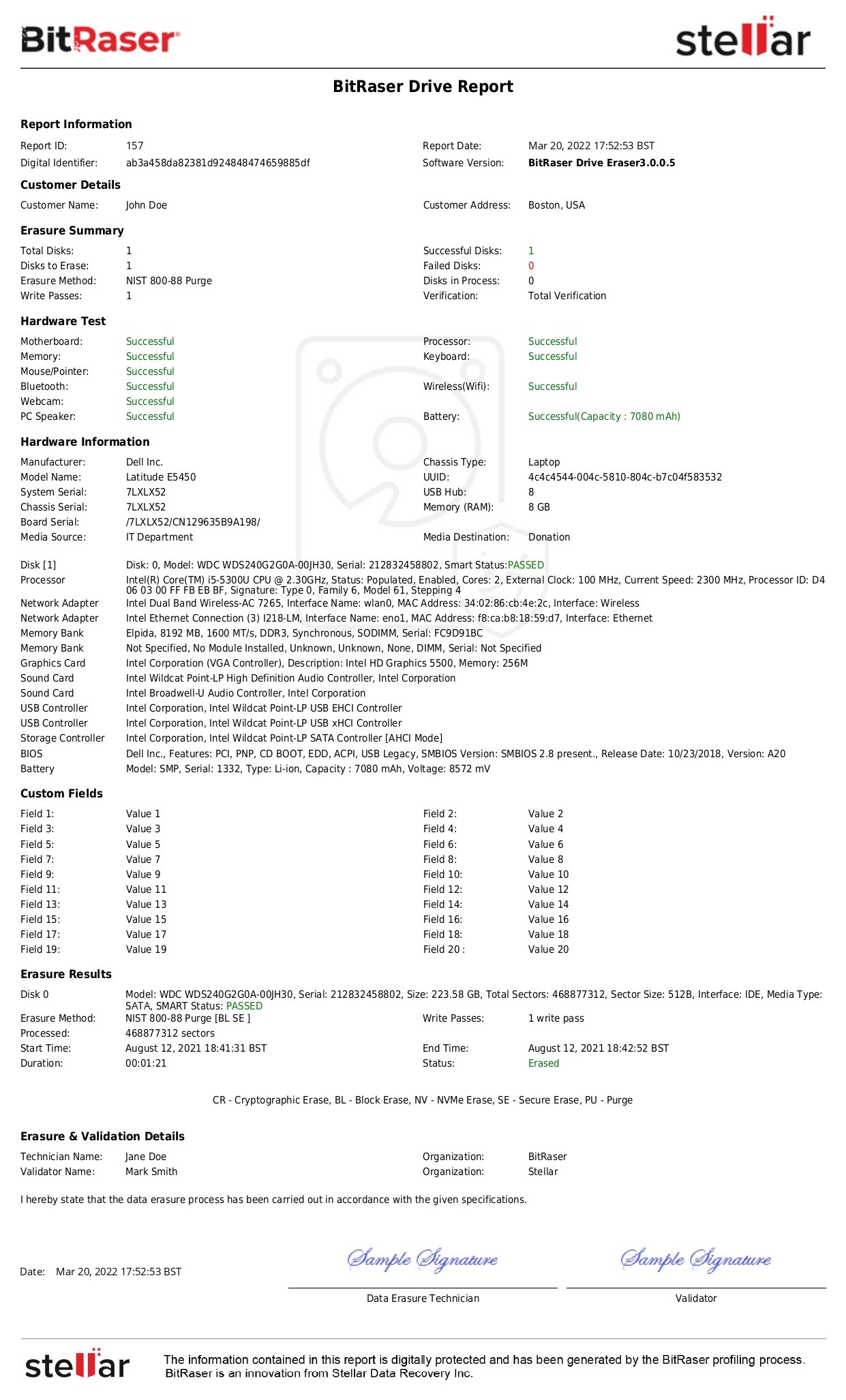

BitRaser offers a software portfolio that helps ITADs erase, verify, and diagnose devices. The erasure software allows data to be erased from all kinds of drives and devices maintaining a record of every erased device on a secure cloud server. BitRaser Drive Verifier on the other hand, validates the presence of any data traces on the erased device to confirm compliance. The BitRaser hardware diagnostics tool helps test device components for PCs, laptops, Macs, and servers, helping ITADs meet Appendix – C of R2v3 guidelines.

1 - ANSI National Accreditation Board